COMMON GROUND

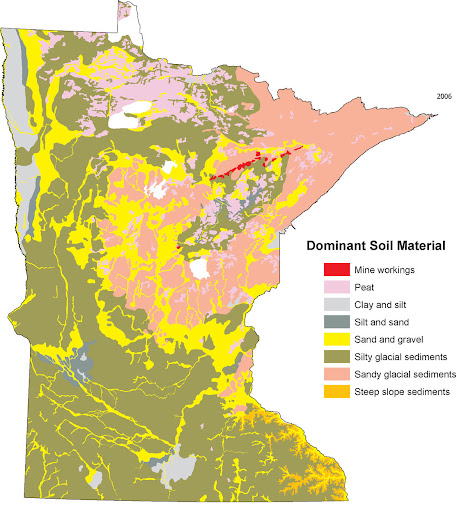

Across the land, across all sites, soil varies significantly. One soil extracted on a construction site will differ from the soil at a neighboring site.

This variability is what makes soil such a standardization challenge, making soil an inherently non-commodified building material. Indeed, the emergence of standard materials from soils is hindered by their high variability and their reliance on local additives and traditional construction methods.

Earth materials are minimally processed, uncooked, unbaked, untreated, raw. Materials are locally sourced and often processed or mixed on-site. The degree to which end-use construction products are engineered from soil varies although the soil remains the ‘feedstock’. How do we find the common ground, the prescribed and characterized soil optimal for buildings? What is the mineralogical classification of clays most suitable, the grain distribution, and optimal mix design?

In this workshop, participants collaboratively built a rammed earth wall, composed of the collection of soils of participants–who vary in diversity very much like their soils–to create a “common ground.” Each student harvested soil from or around their living site. They learned how to assess these individual soils for construction. Then, they built a series of small rammed earth "walletes" made of the different soils brought. Lastly, a large rammed earth wall was made from the soils brought by students and faculty.

This variability is what makes soil such a standardization challenge, making soil an inherently non-commodified building material. Indeed, the emergence of standard materials from soils is hindered by their high variability and their reliance on local additives and traditional construction methods.

Earth materials are minimally processed, uncooked, unbaked, untreated, raw. Materials are locally sourced and often processed or mixed on-site. The degree to which end-use construction products are engineered from soil varies although the soil remains the ‘feedstock’. How do we find the common ground, the prescribed and characterized soil optimal for buildings? What is the mineralogical classification of clays most suitable, the grain distribution, and optimal mix design?

In this workshop, participants collaboratively built a rammed earth wall, composed of the collection of soils of participants–who vary in diversity very much like their soils–to create a “common ground.” Each student harvested soil from or around their living site. They learned how to assess these individual soils for construction. Then, they built a series of small rammed earth "walletes" made of the different soils brought. Lastly, a large rammed earth wall was made from the soils brought by students and faculty.

date:

Sept 2020

– May 2022

collaborators:

Malini Srivastava, Meg Lundquist

location:

School of Architecture, College of Design, University of Minnesota